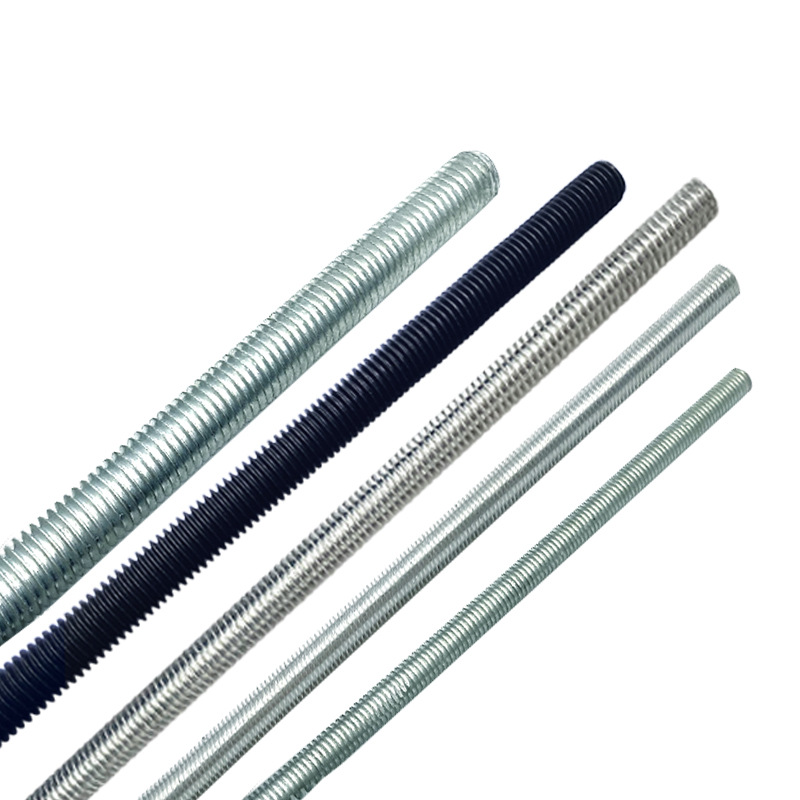

stud bolt

A stud bolt is a critical fastening component designed with threads on both ends, serving as an essential element in various industrial applications. These precision-engineered fasteners consist of a cylindrical shaft with external threading that extends either partially or fully along its length. Stud bolts are widely utilized in high-pressure applications, particularly in flanged connections, pressure vessels, and pipeline systems. They provide exceptional tensile strength and reliable clamping force, making them indispensable in maintaining the integrity of critical joints. The design allows for optimal load distribution and superior resistance to vibration and thermal cycling. Manufacturing processes typically involve high-grade alloy steels, with various coating options available to enhance corrosion resistance. Stud bolts are manufactured to meet specific international standards, including ASTM and DIN specifications, ensuring consistent quality and performance across different applications. Their versatility extends to various industries, including petrochemical, power generation, and heavy machinery manufacturing, where they play a crucial role in maintaining structural integrity and operational safety.