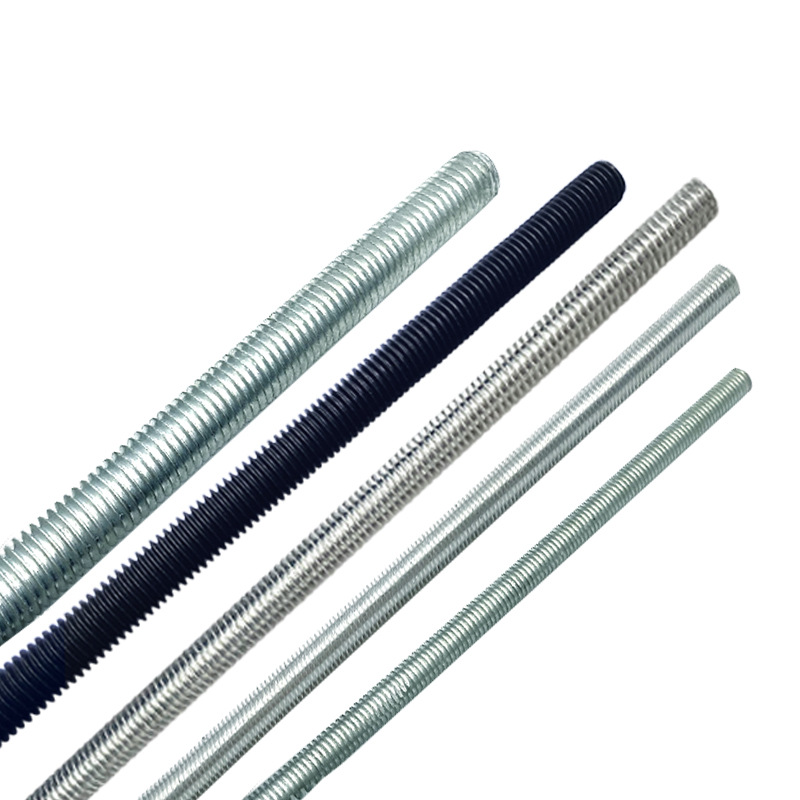

Versatile Material and Coating Options

The hex flange bolt's design accommodates an extensive range of material compositions and surface treatments, making it exceptionally versatile across different applications and environments. From standard carbon steel to specialized alloys like stainless steel and titanium, these bolts can be manufactured to meet specific strength, corrosion resistance, and temperature requirements. Various surface treatments and coatings, including zinc plating, hot-dip galvanization, and specialized anti-corrosion coatings, can be applied to enhance performance in challenging environments. This adaptability extends to the flange surface itself, which can be manufactured with different finishes to optimize friction characteristics for specific applications. The ability to select from multiple material and coating combinations ensures that hex flange bolts can be precisely matched to application requirements, whether they involve extreme temperatures, chemical exposure, or high mechanical stress.