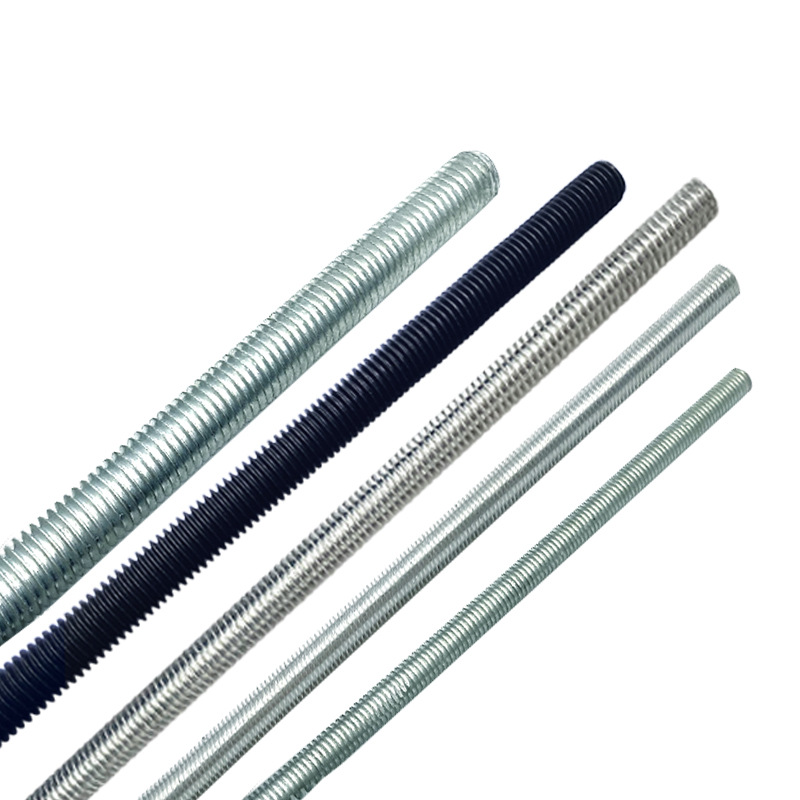

astm a193b7 a1942h

The ASTM A193B7 and A194 2H represent a crucial combination in high-temperature bolting applications. The A193B7 is a high-strength alloy steel bolt material, specifically designed for elevated temperature service, while the A194 2H serves as its companion heavy hex nut. This fastener system is primarily manufactured from chromium-molybdenum steel, offering exceptional strength and durability under demanding conditions. The material exhibits remarkable resistance to high temperatures up to 1000°F (538°C), making it ideal for pressure vessel connections, pipeline flanges, and various high-pressure applications. These fasteners undergo careful heat treatment processes to achieve optimal mechanical properties, including high yield strength and excellent creep resistance. The combination is particularly valued in petrochemical plants, refineries, and power generation facilities where reliable performance under extreme conditions is essential. The standardized manufacturing process ensures consistent quality and interchangeability, while the materials resistance to stress corrosion cracking and thermal fatigue makes it a reliable choice for critical applications.