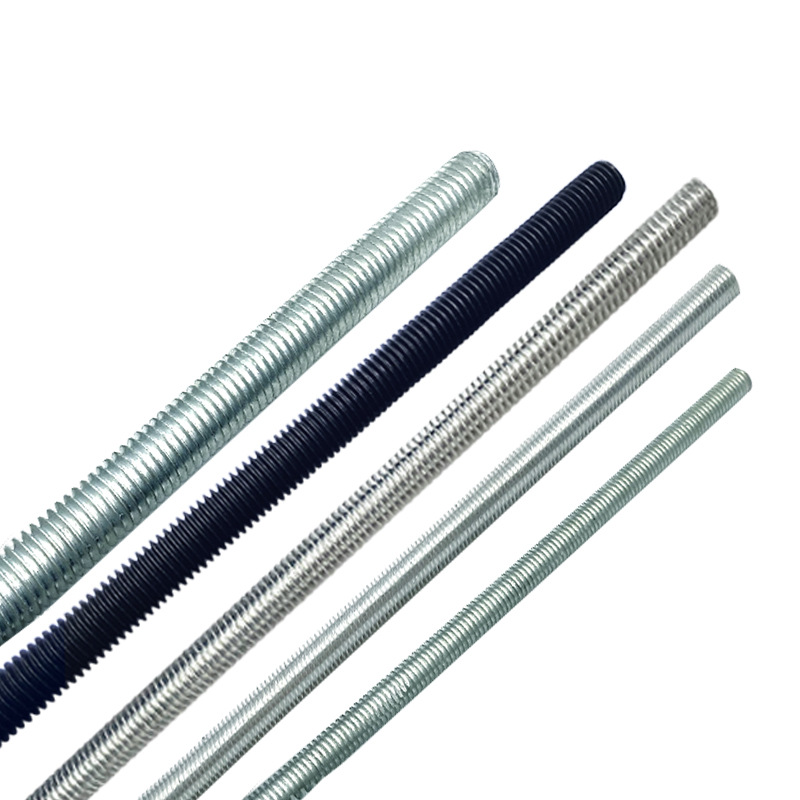

threaded rod

A threaded rod, also known as a stud bolt or all-thread rod, is a crucial fastening component featuring continuous helical threads running along its entire length. This versatile mechanical element serves as an essential connector in various construction, manufacturing, and assembly applications. The rod's design allows for precise adjustments and secure connections through the use of nuts that can be positioned anywhere along its length. Manufactured from various materials including stainless steel, carbon steel, and brass, threaded rods come in different diameters and thread patterns to suit specific requirements. The continuous threading enables users to cut the rod to custom lengths while maintaining full functionality. These rods excel in applications requiring long-term structural support, such as hanging pipes, electrical conduits, and HVAC systems. They are also integral in machinery assembly, furniture manufacturing, and architectural projects where adjustable connections are necessary. The thread design follows standardized specifications, ensuring compatibility with standard nuts and allowing for universal application across different industries. Their durability and load-bearing capacity make them indispensable in both light-duty and heavy-duty applications.