bolt china

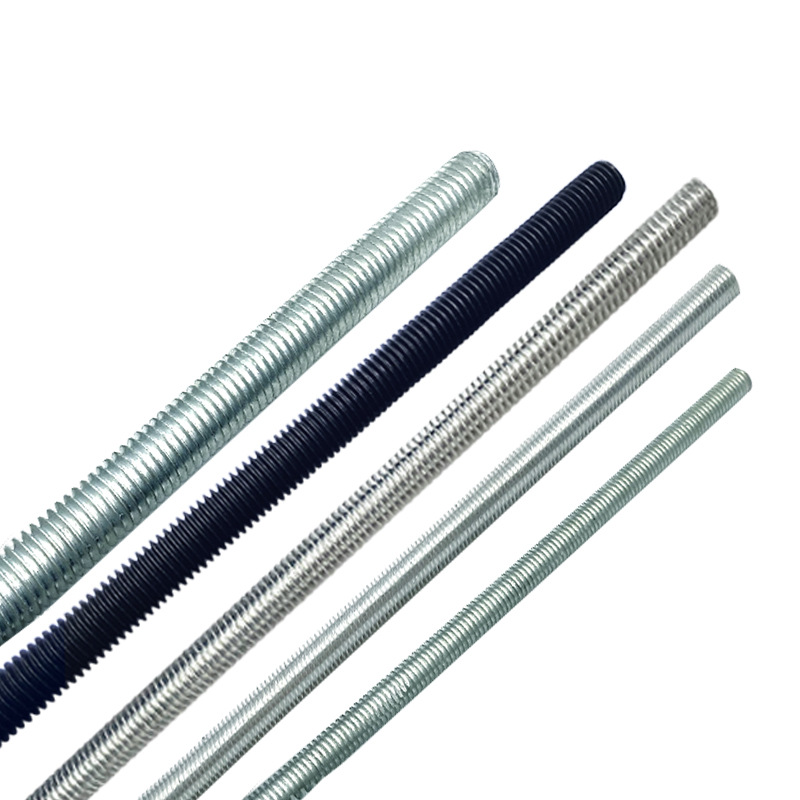

Bolt China represents a significant advancement in industrial fastening technology, combining traditional Chinese manufacturing expertise with modern engineering principles. These precision-engineered fasteners are manufactured to meet international standards while offering cost-effective solutions for various industries. The bolts feature high-tensile strength steel construction, with carefully controlled heat treatment processes ensuring optimal hardness and durability. Available in multiple specifications ranging from M2 to M20, these bolts accommodate diverse application requirements across construction, automotive, machinery, and infrastructure sectors. The manufacturing process incorporates advanced quality control measures, including automated inspection systems and metallurgical testing, ensuring consistency and reliability. Each bolt undergoes rigorous testing for tensile strength, shear resistance, and corrosion protection, meeting or exceeding ISO and DIN standards. The surface treatment options include hot-dip galvanization, zinc plating, and black oxide coating, providing excellent corrosion resistance and extended service life. These bolts are particularly notable for their precise threading and head formation, ensuring secure fastening and easy installation in various environmental conditions.