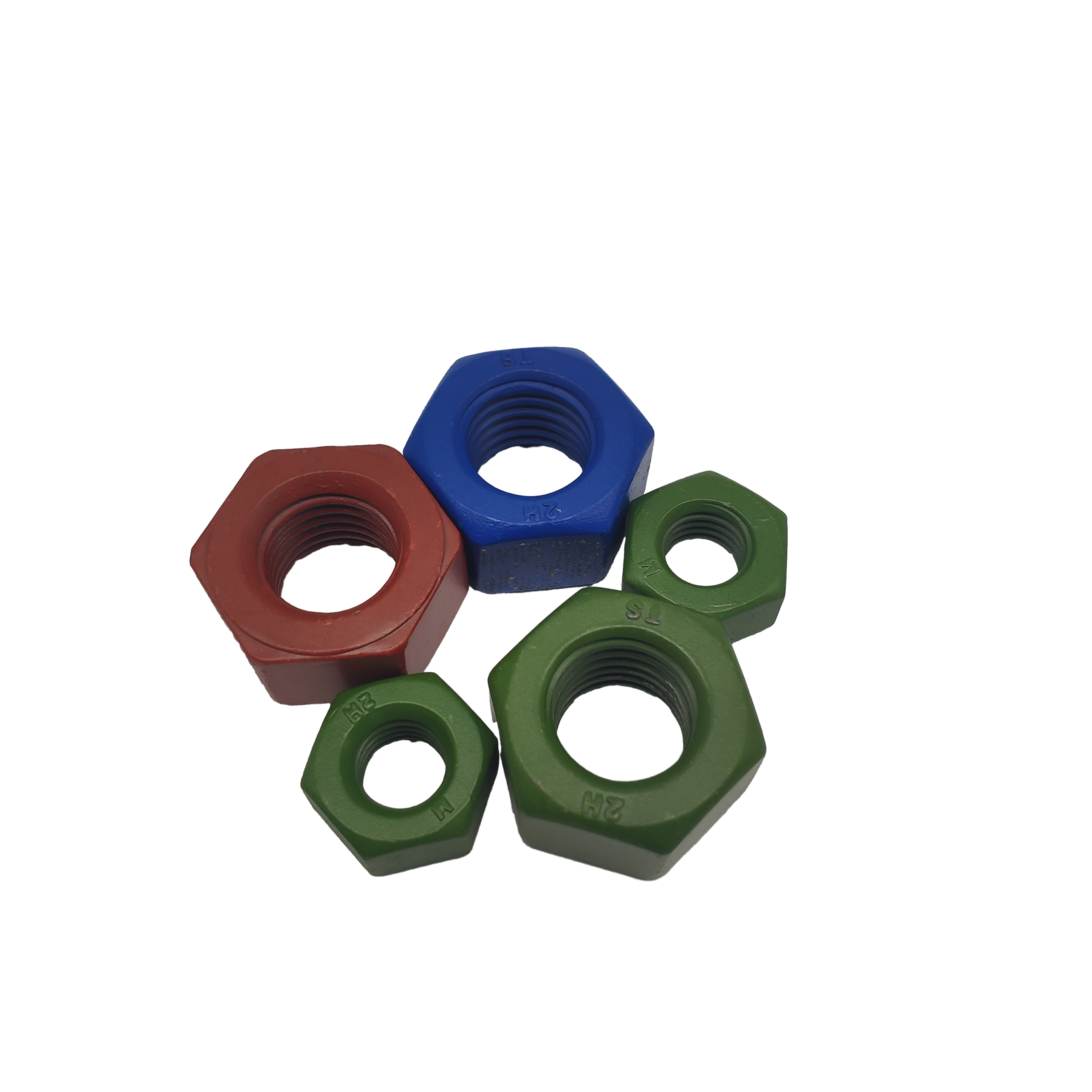

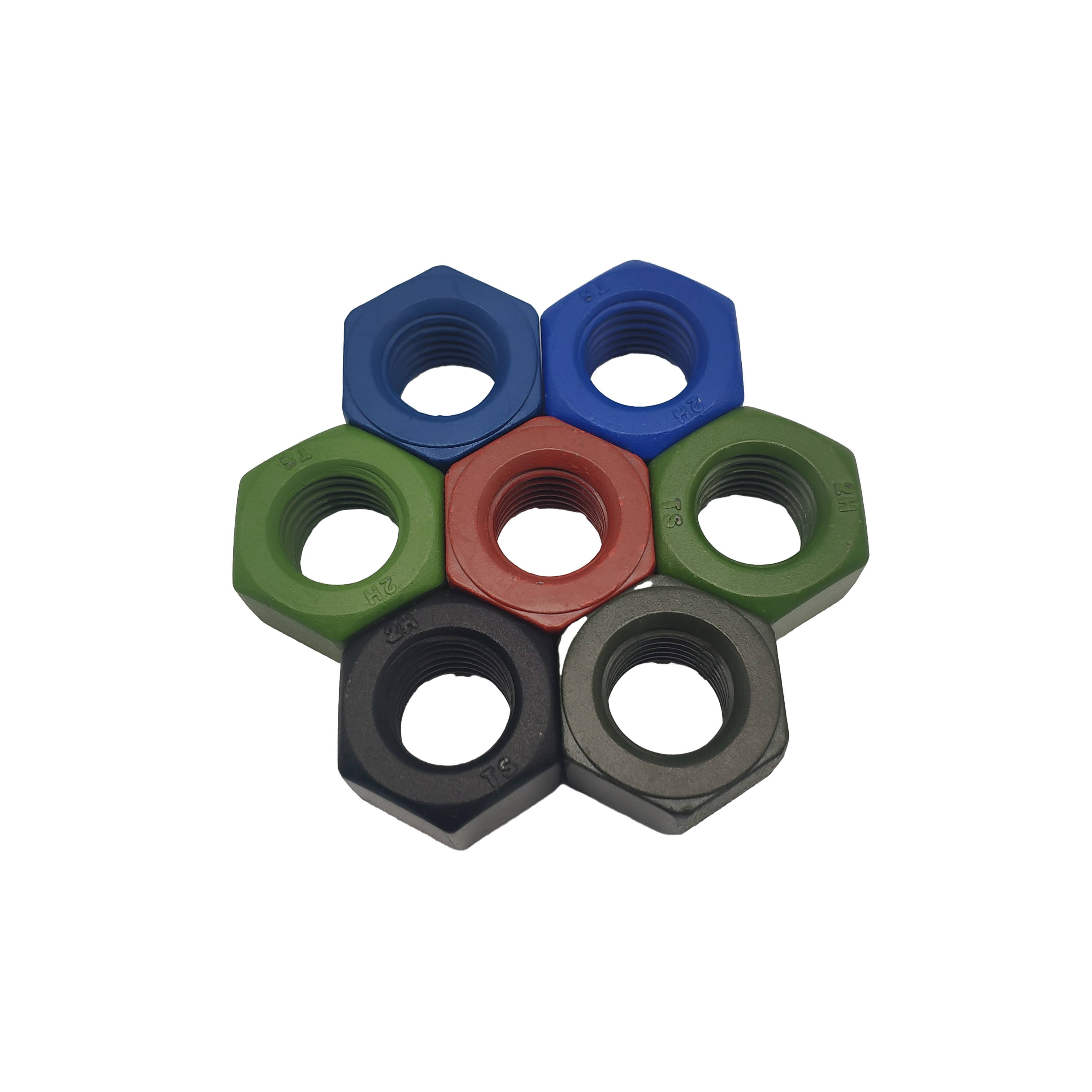

hex nut types

Hex nuts are essential fastening components characterized by their hexagonal shape and internal threading, serving as crucial elements in various assembly applications. These standardized fasteners come in multiple types, including standard hex nuts, heavy hex nuts, jam nuts, and lock nuts, each designed for specific use cases and load requirements. The hexagonal shape enables easy gripping with wrenches or other tools, facilitating efficient installation and removal. Manufactured from various materials including steel, stainless steel, brass, and nylon, hex nuts offer different levels of strength, corrosion resistance, and chemical compatibility. Their internal threading matches corresponding bolts or screws, creating secure mechanical connections in construction, manufacturing, automotive, and industrial applications. Modern hex nuts incorporate various features such as nylon inserts, serrated flanges, or split designs to prevent loosening under vibration or dynamic loads. Available in both metric and imperial sizes, hex nuts conform to international standards like ISO, DIN, and ASME, ensuring compatibility and reliability across different manufacturing specifications.