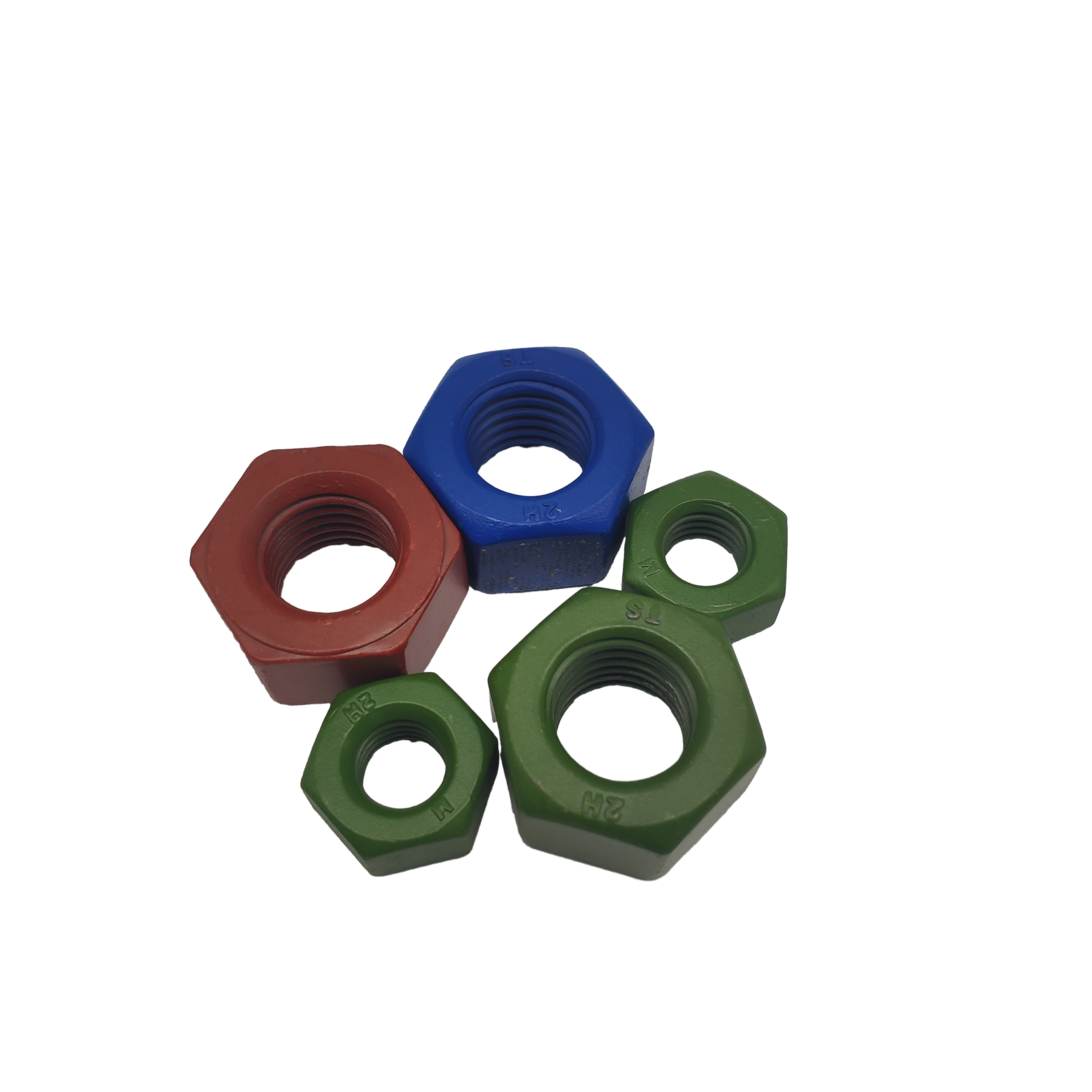

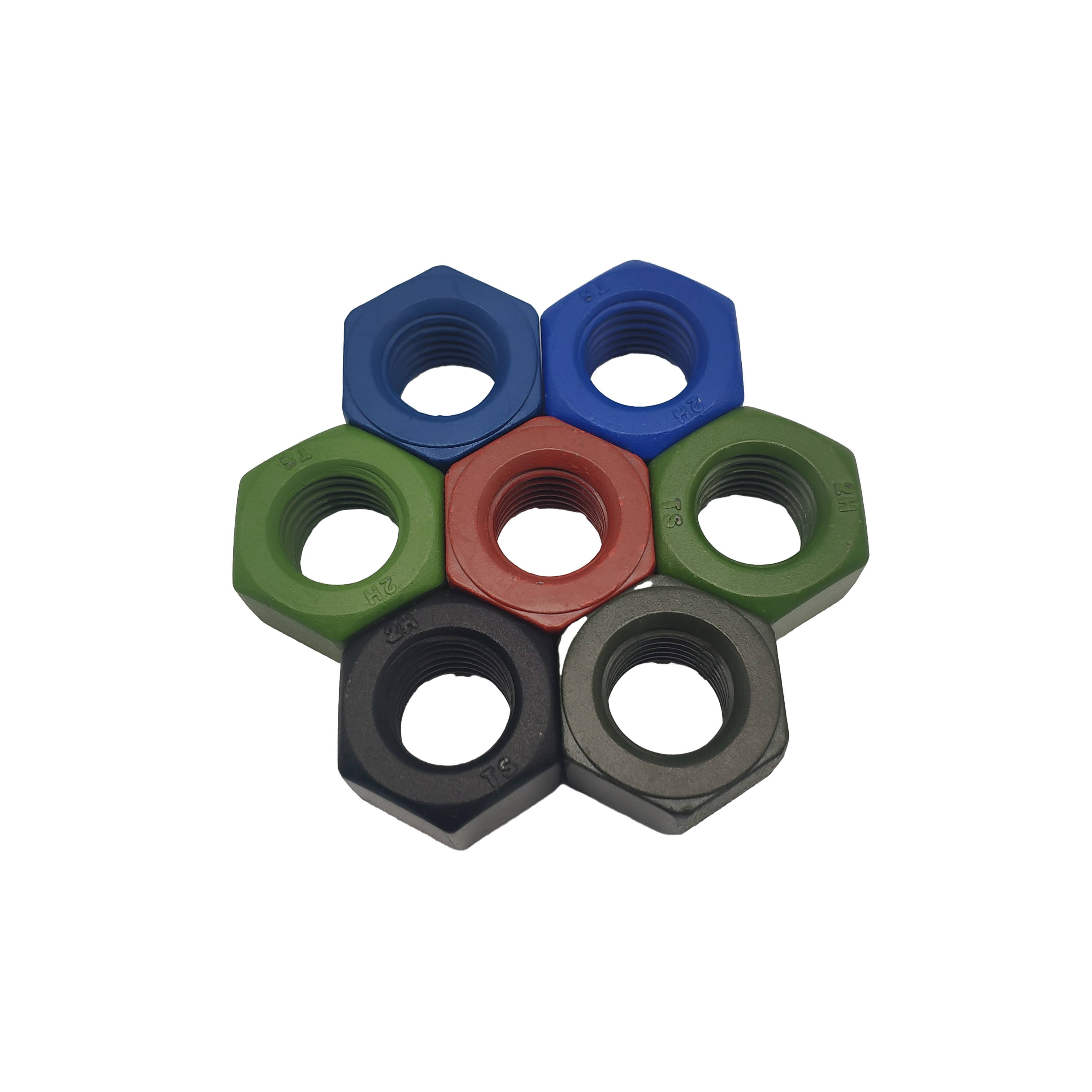

hex nut suppliers

Hex nut suppliers play a crucial role in the industrial fastening sector by providing essential components for various assembly applications. These suppliers specialize in manufacturing and distributing hexagonal nuts that serve as fundamental connecting elements in mechanical assemblies. Modern hex nut suppliers utilize advanced manufacturing processes, including precision CNC machining and automated quality control systems, to ensure consistent product quality and dimensional accuracy. They offer a comprehensive range of hex nuts in different materials such as stainless steel, carbon steel, brass, and aluminum, catering to diverse industry requirements. These suppliers maintain extensive inventories of standard and custom-sized hex nuts, complying with international standards like ISO, DIN, and ASTM. Their product portfolios typically include both metric and imperial sizes, with various thread patterns and strength grades available to meet specific application needs. Many leading suppliers also provide value-added services such as material certification, plating options, and technical consultation to assist customers in selecting the most suitable hex nuts for their projects. The significance of reliable hex nut suppliers extends across multiple sectors, including automotive, construction, aerospace, and general manufacturing, where their products contribute to the structural integrity and safety of assembled components.