Versatile Application Range

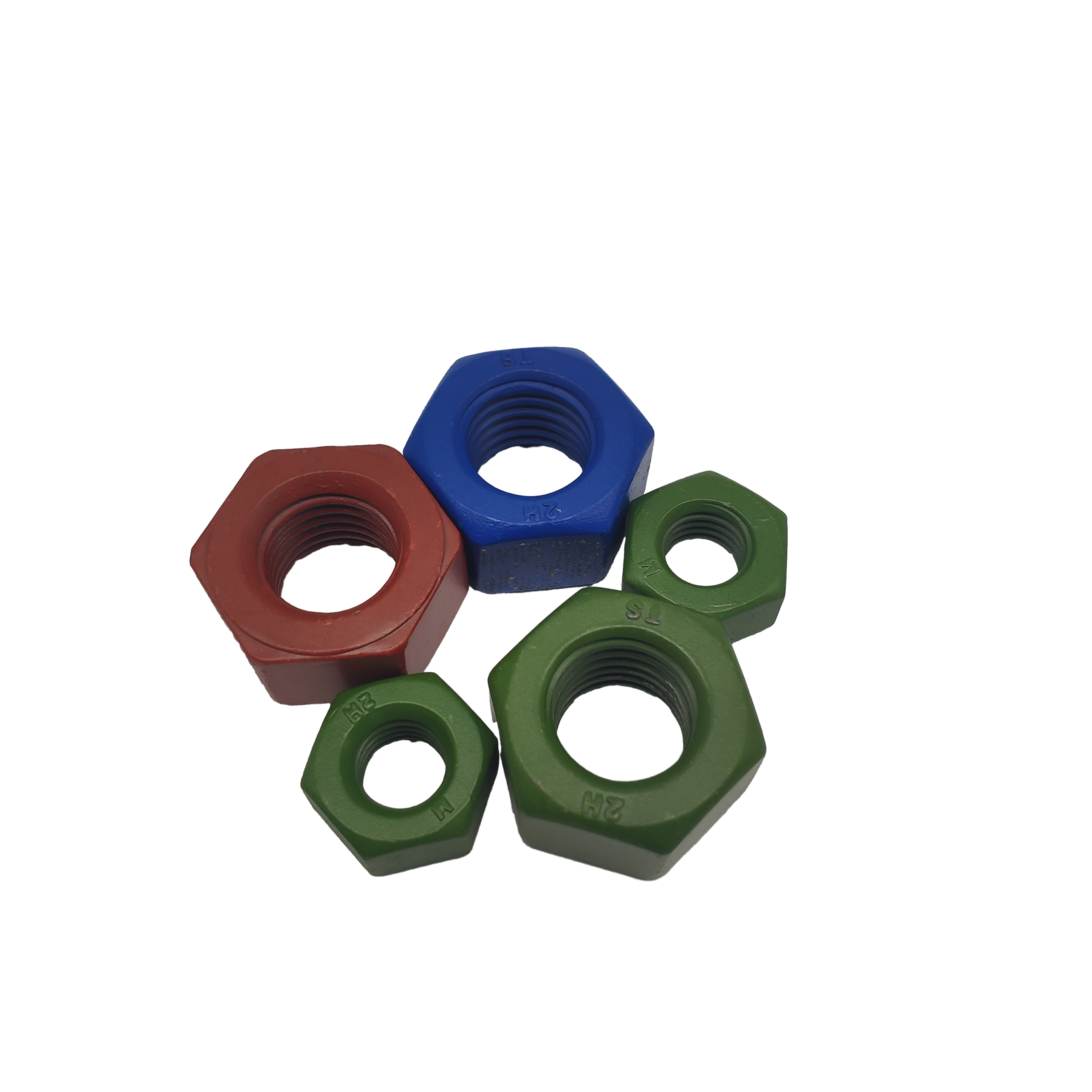

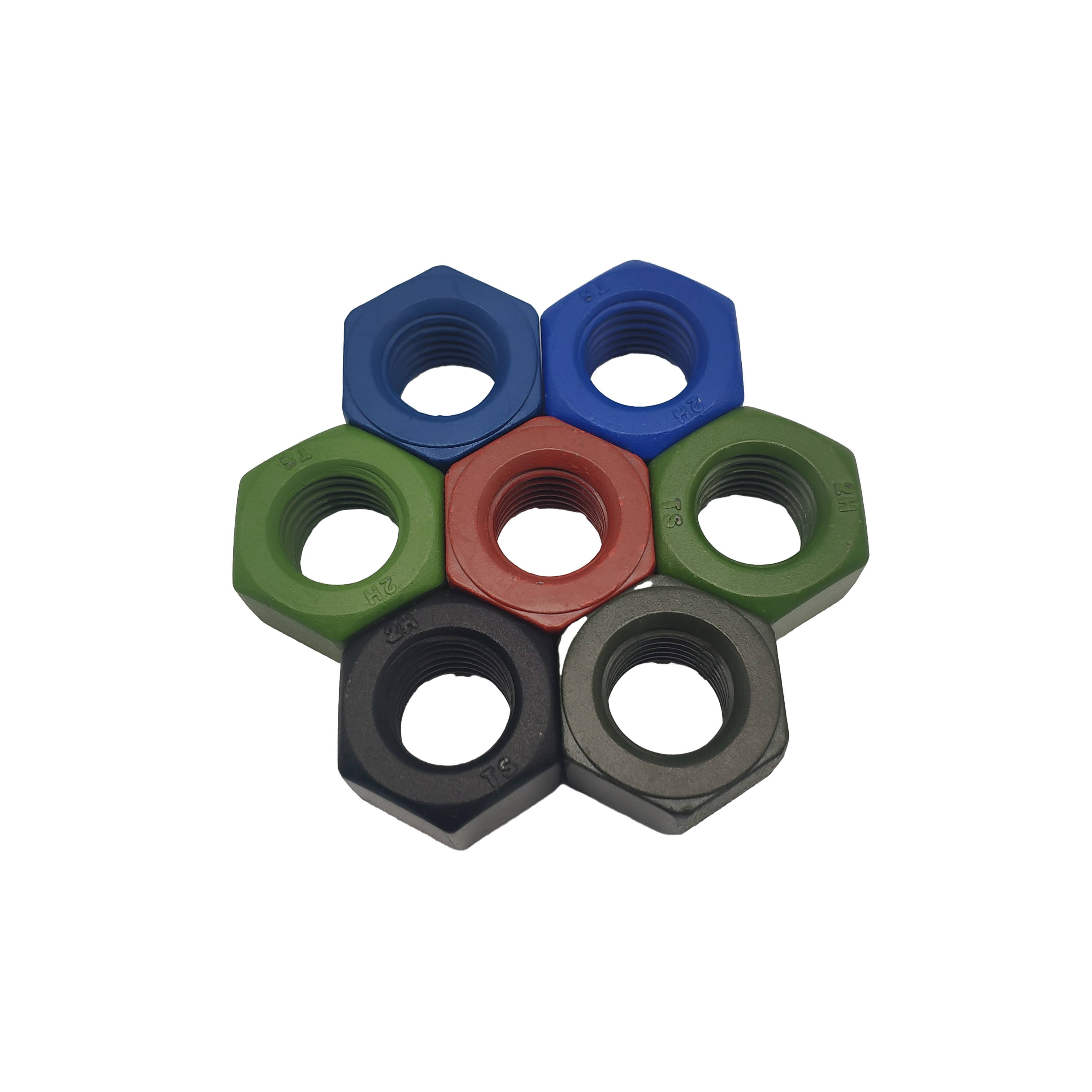

Prevailing torque hex nuts demonstrate exceptional versatility across numerous industries and applications. Their adaptability is evident in their wide range of sizes, materials, and finish options, allowing engineers to select the optimal combination for specific operating conditions. The nuts perform reliably in extreme temperatures, corrosive environments, and high-stress applications, making them suitable for aerospace, automotive, marine, and industrial use. This versatility extends to their compatibility with various bolt types and materials, providing flexibility in design and implementation. The nuts can be manufactured to meet different international standards and specifications, ensuring global compatibility and compliance with industry requirements. Their proven performance in critical applications has made them a preferred choice for engineers seeking reliable fastening solutions across diverse operating environments.