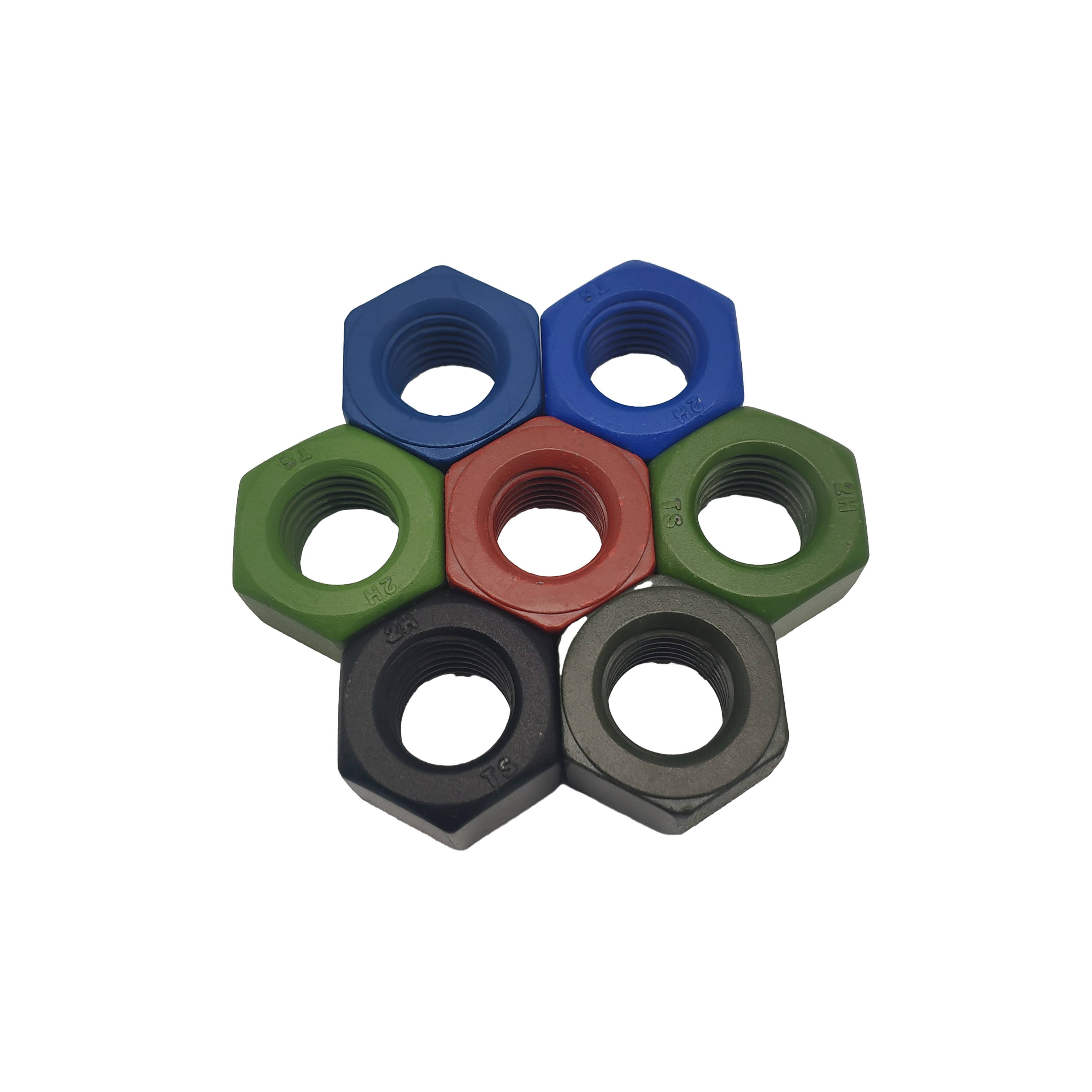

structural nuts

Structural nuts are essential fastening components engineered to provide secure connections in construction and industrial applications. These specialized fasteners are designed with precision-machined threads and robust geometric profiles to ensure optimal load distribution and structural integrity. Manufactured from high-grade materials such as carbon steel, stainless steel, or alloy steel, structural nuts offer exceptional strength and durability under demanding conditions. They feature specific thread patterns and dimensional tolerances that comply with international standards, making them suitable for critical load-bearing applications. The nuts incorporate various safety features, including self-locking mechanisms or deformation-resistant designs, to prevent loosening under vibration or dynamic loads. Their versatile design allows for both permanent and temporary connections, while their standardized specifications ensure compatibility with corresponding structural bolts across different applications. These components are particularly valuable in steel construction, bridge building, heavy machinery assembly, and other applications where reliable mechanical fastening is crucial for structural stability and safety.