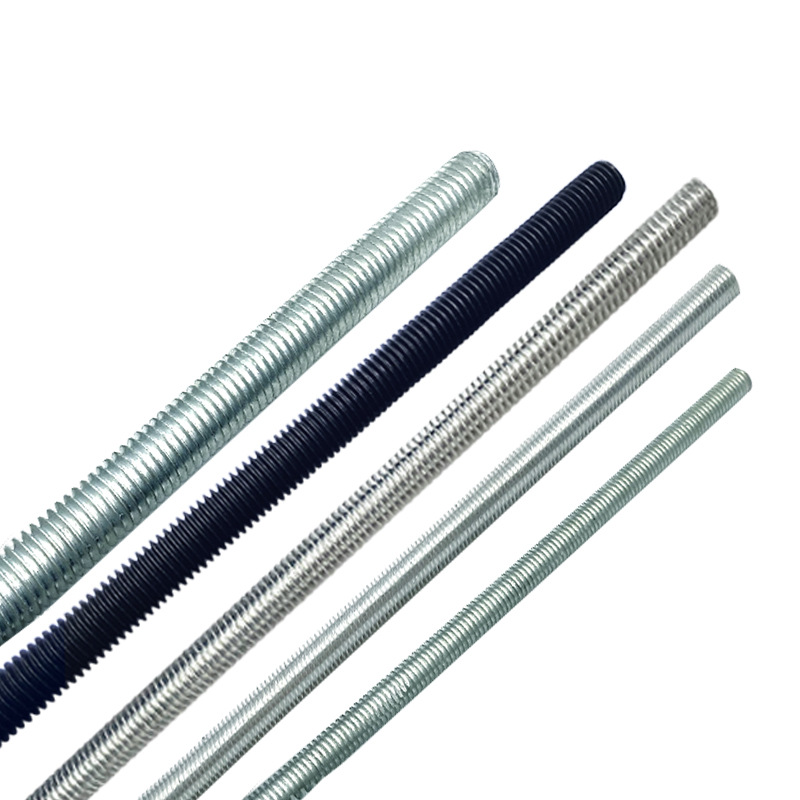

fully threaded rod

A fully threaded rod, also known as a threaded bar or all-thread rod, is an essential industrial fastening component that features continuous threading along its entire length. This versatile fastener is manufactured from various materials, including stainless steel, carbon steel, and galvanized steel, offering different levels of corrosion resistance and strength. The continuous thread pattern allows for maximum adjustability and flexibility in securing components, making it ideal for numerous construction and manufacturing applications. The rod's design enables users to cut it to any desired length while maintaining its threading functionality, providing cost-effective solutions for various projects. These rods come in different diameters and thread patterns, accommodating diverse load-bearing requirements and installation specifications. Their robust construction ensures reliable performance in both tension and compression applications, while their full-length threading facilitates precise adjustments during installation and maintenance. The threading process follows strict quality control measures to ensure consistent pitch and depth, guaranteeing optimal engagement with nuts and other threaded components. This attention to manufacturing detail results in a product that maintains its structural integrity even under demanding conditions, making it a trusted choice for professional contractors and engineers.