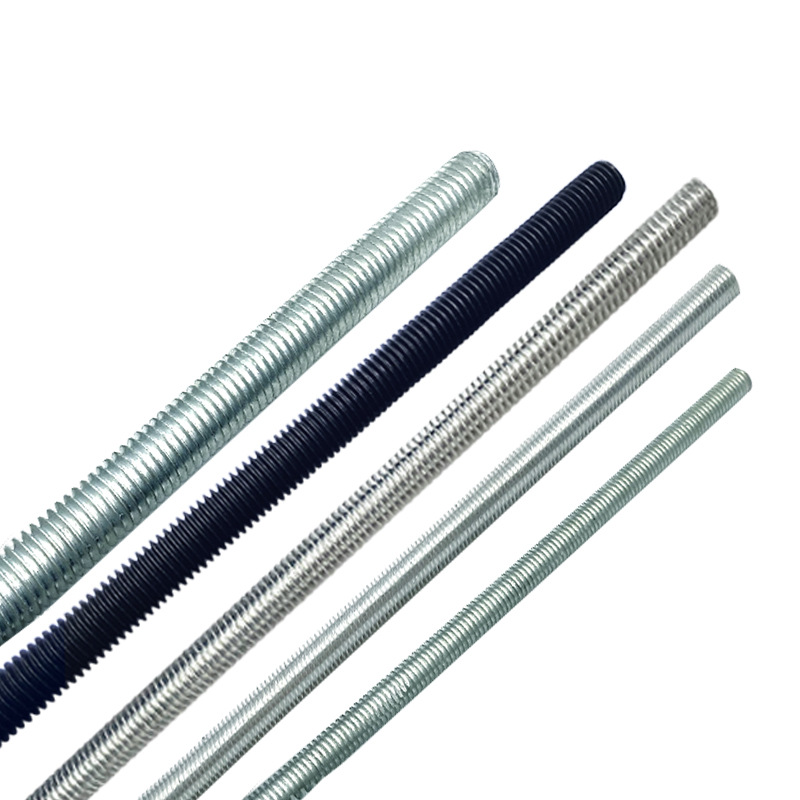

bolt

A bolt is a fundamental mechanical fastener that plays a crucial role in joining and securing various components together. This cylindrical fastener features an external helical thread and typically comes with a head designed for installation and removal using specific tools. Modern bolts are manufactured using advanced metallurgical processes, incorporating materials like high-grade steel, stainless steel, or specialized alloys to ensure optimal performance under diverse conditions. The threading pattern, whether coarse or fine, is precisely engineered to provide maximum holding power while allowing for efficient assembly and disassembly. Bolts come in various sizes, strengths, and designs, each optimized for specific applications ranging from lightweight consumer products to heavy industrial machinery. The head design may vary from hexagonal to square, socket, or other specialized shapes, accommodating different installation requirements and space constraints. Advanced coating technologies are often applied to enhance corrosion resistance and longevity, making bolts suitable for both indoor and outdoor applications. The load-bearing capacity of bolts is carefully calculated and standardized, ensuring reliable performance in critical applications where structural integrity is paramount.