bolt factory

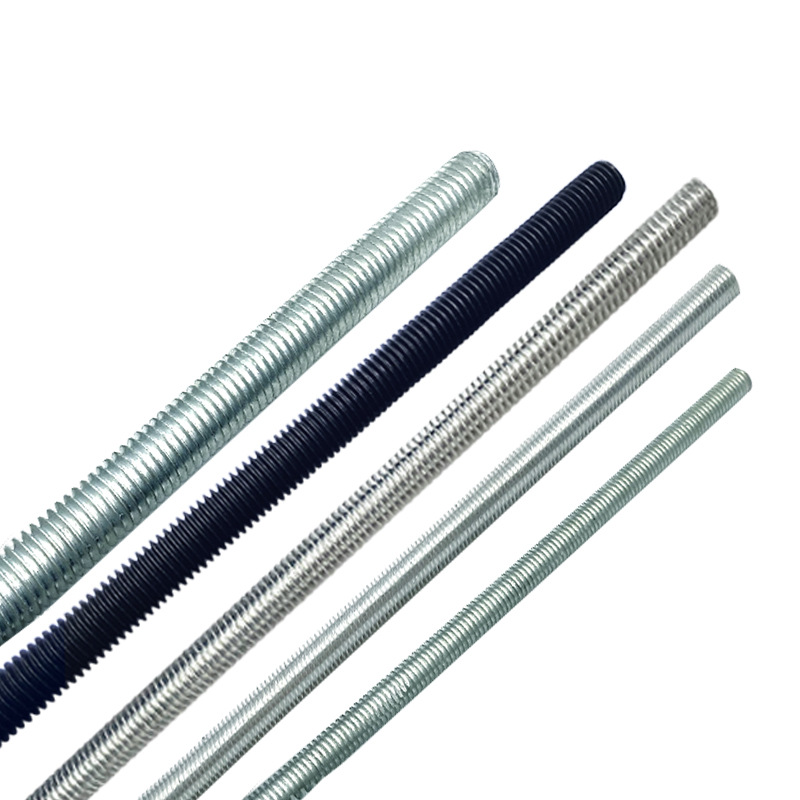

A bolt factory represents a sophisticated manufacturing facility dedicated to producing high-quality fasteners essential for various industries. Modern bolt factories integrate advanced automation systems, precision machinery, and quality control processes to ensure consistent production of standardized bolts. These facilities typically feature multiple production lines equipped with cold forming machines, thread rolling equipment, and heat treatment furnaces. The manufacturing process begins with raw material selection, primarily steel wire or bars, which undergoes systematic transformation through cutting, heading, threading, and finishing operations. Quality assurance laboratories within the facility conduct rigorous testing for mechanical properties, dimensional accuracy, and material composition. The factory's production capabilities extend to various bolt types, including hex bolts, carriage bolts, flange bolts, and specialty fasteners, meeting diverse industry specifications and standards. Advanced inventory management systems and efficient logistics operations ensure timely delivery and stock maintenance. The facility also maintains strict environmental controls and implements sustainable manufacturing practices to minimize waste and energy consumption.