Essential Components for Modern Mechanical Fastening

In the vast world of mechanical fasteners, hex nuts stand as fundamental components that have revolutionized how we join and secure materials. These six-sided wonders have become indispensable in countless applications, from everyday household repairs to complex industrial machinery. Their simple yet ingenious design has made them the preferred choice for engineers, manufacturers, and DIY enthusiasts alike.

While seemingly basic in appearance, hex nuts represent a perfect fusion of engineering principles and practical functionality. Their hexagonal shape isn't just for aesthetics - it's a carefully considered design that offers superior grip and torque application compared to other fastener types. This makes them exceptionally versatile across various industries and applications.

Design Features and Engineering Excellence

Geometric Precision and Tool Compatibility

The hexagonal shape of hex nuts is far from arbitrary. This geometric design allows for optimal tool engagement from multiple angles, making them incredibly practical in confined spaces. The six flat surfaces provide excellent contact points for wrenches and sockets, enabling consistent torque application without the risk of slipping that might occur with other shapes.

Modern hex nuts are manufactured with precise dimensional tolerances, ensuring compatibility with standardized tools and fasteners worldwide. This standardization has made hex nuts a reliable choice in global manufacturing and construction projects, where consistency and interchangeability are crucial.

Material Innovation and Performance

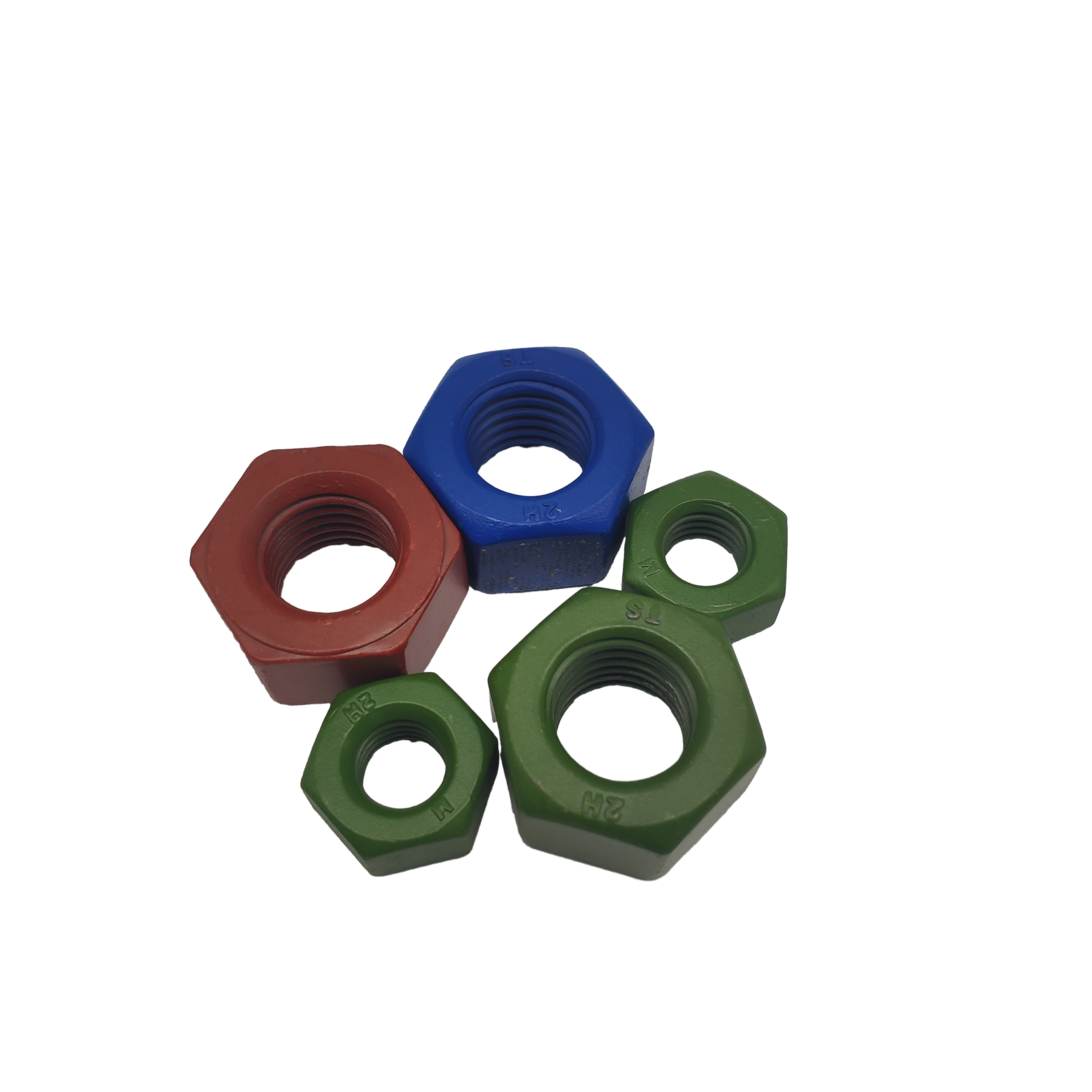

Today's hex nuts are available in an impressive array of materials, each engineered for specific applications. From carbon steel and stainless steel to brass and nylon, manufacturers can select the perfect material to match their requirements for strength, corrosion resistance, and chemical compatibility.

Advanced coating technologies have further enhanced the capabilities of hex nuts. Zinc plating, hot-dip galvanization, and other surface treatments provide additional protection against harsh environmental conditions, extending the service life of these essential components.

Installation Benefits and Efficiency

Speed and Precision in Assembly

The installation process for hex nuts is remarkably straightforward, thanks to their user-friendly design. The flat surfaces allow for quick tool engagement, reducing assembly time significantly compared to alternative fastening methods. This efficiency translates directly into cost savings in manufacturing and maintenance operations.

The hexagonal shape also enables precise torque application, crucial for maintaining proper clamping force. This precision helps prevent both over-tightening and under-tightening, which could lead to joint failure or equipment damage. Professional installers particularly appreciate this aspect during high-volume assembly operations.

Maintenance and Accessibility

When it comes to maintenance and repairs, hex nuts truly shine. Their design facilitates easy access for periodic inspections and adjustments, ensuring equipment reliability over time. The ability to quickly loosen and retighten hex nuts makes routine maintenance tasks more efficient and less labor-intensive.

The standardized design also means that replacement parts are readily available worldwide, reducing downtime and inventory management challenges for maintenance teams. This universal availability has made hex nuts a preferred choice in industries where equipment reliability is paramount.

Industrial Applications and Versatility

Heavy Manufacturing Implementation

In heavy industry, hex nuts play a crucial role in assembling and maintaining large machinery and equipment. Their robust design and ability to withstand high loads make them ideal for applications in construction equipment, industrial machinery, and heavy transportation vehicles. The reliability of hex nuts in these demanding environments has made them indispensable in modern manufacturing.

Manufacturing facilities rely on hex nuts for their production lines, conveyor systems, and auxiliary equipment. The ease of installation and maintenance helps minimize production disruptions while ensuring consistent operation under challenging conditions.

Specialized Industry Solutions

Beyond traditional manufacturing, hex nuts have found their way into specialized industries with unique requirements. In aerospace applications, high-performance hex nuts made from exotic alloys provide the perfect combination of strength and weight savings. The automotive industry utilizes specially coated hex nuts that resist vibration loosening and corrosion.

The chemical processing industry benefits from hex nuts manufactured from corrosion-resistant materials, ensuring long-term reliability in aggressive environments. Similarly, the food and beverage industry relies on stainless steel hex nuts that meet strict hygiene standards while providing necessary structural integrity.

Future Trends and Innovations

Advanced Manufacturing Technologies

The future of hex nuts looks promising with the advent of new manufacturing technologies. 3D printing and advanced machining techniques are enabling the production of custom hex nuts with complex geometries and integrated features. These innovations are opening new possibilities for specialized applications and improved performance.

Smart manufacturing processes are also revolutionizing hex nut production, incorporating real-time quality control and automated inspection systems. This ensures unprecedented consistency and reliability in the finished products while reducing manufacturing costs.

Sustainable Development

Environmental consciousness is driving innovation in hex nut manufacturing. New materials and production methods focus on reducing environmental impact while maintaining or improving performance characteristics. Recycled materials and eco-friendly coatings are becoming increasingly common in hex nut production.

The industry is also exploring ways to optimize hex nut designs for easier recycling at the end of their service life. This approach aligns with global sustainability initiatives while meeting the growing demand for environmentally responsible industrial components.

Frequently Asked Questions

What makes hex nuts superior to other fastener types?

Hex nuts offer several advantages over other fasteners, including better tool engagement, consistent torque application, and universal compatibility with standard tools. Their six-sided design provides multiple contact points for wrenches and sockets, making them easier to install and remove while reducing the risk of slipping during installation.

How do I select the right material for hex nuts in my application?

Material selection depends on various factors including environmental conditions, load requirements, and chemical exposure. Consider factors such as corrosion resistance, temperature range, and mechanical strength when choosing between options like carbon steel, stainless steel, brass, or synthetic materials. Consulting with a fastener specialist can help ensure the optimal choice for your specific needs.

What maintenance practices ensure optimal performance of hex nuts?

Regular inspection for wear, damage, or corrosion is essential. Maintain proper torque specifications during installation and periodic checks. Clean threads before assembly and use appropriate lubricants when required. For critical applications, implement a scheduled replacement program based on service conditions and manufacturer recommendations.