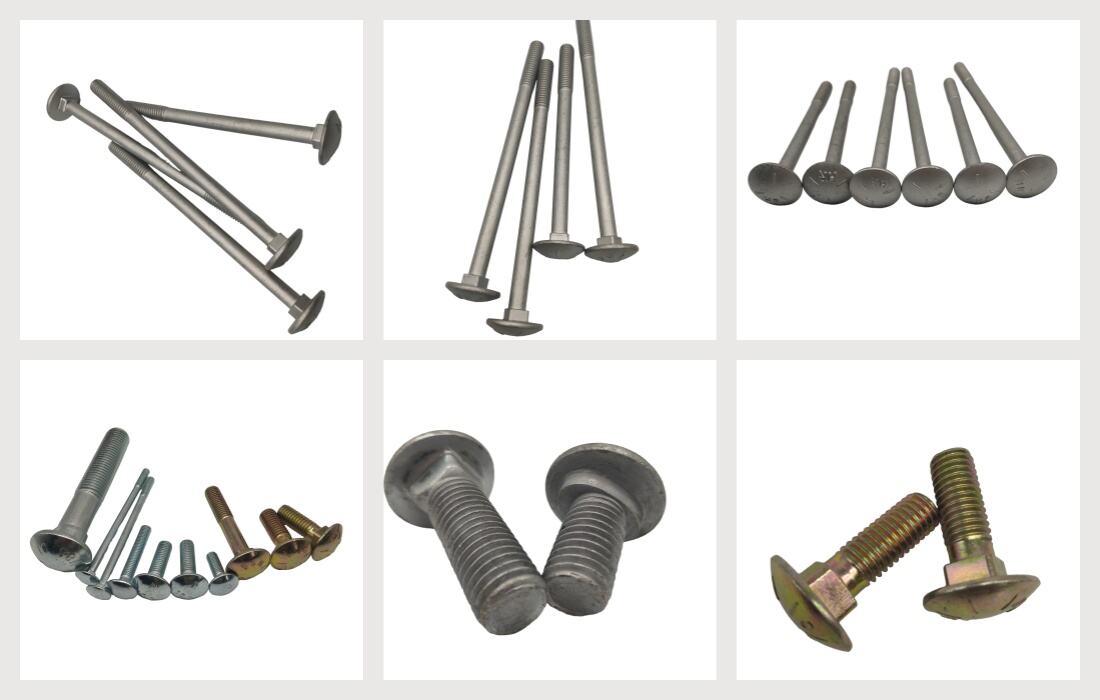

screws and bolts price

Understanding screws and bolts pricing is crucial for both construction professionals and DIY enthusiasts. The pricing structure reflects various factors including material composition, size specifications, coating types, and manufacturing quality. Standard steel screws and bolts typically represent the most economical option, while stainless steel and specialized alloys command premium prices due to their enhanced durability and corrosion resistance. Market prices fluctuate based on raw material costs, manufacturing processes, bulk quantities, and specific industry demands. Modern manufacturing techniques have introduced precision-engineered fasteners with specialized threading, head designs, and protective coatings, all of which influence the final price point. The global supply chain also impacts pricing, with factors such as transportation costs, import duties, and regional availability playing significant roles. Understanding these price variations helps buyers make informed decisions based on their specific application requirements, whether for industrial construction, automotive assembly, or household repairs.