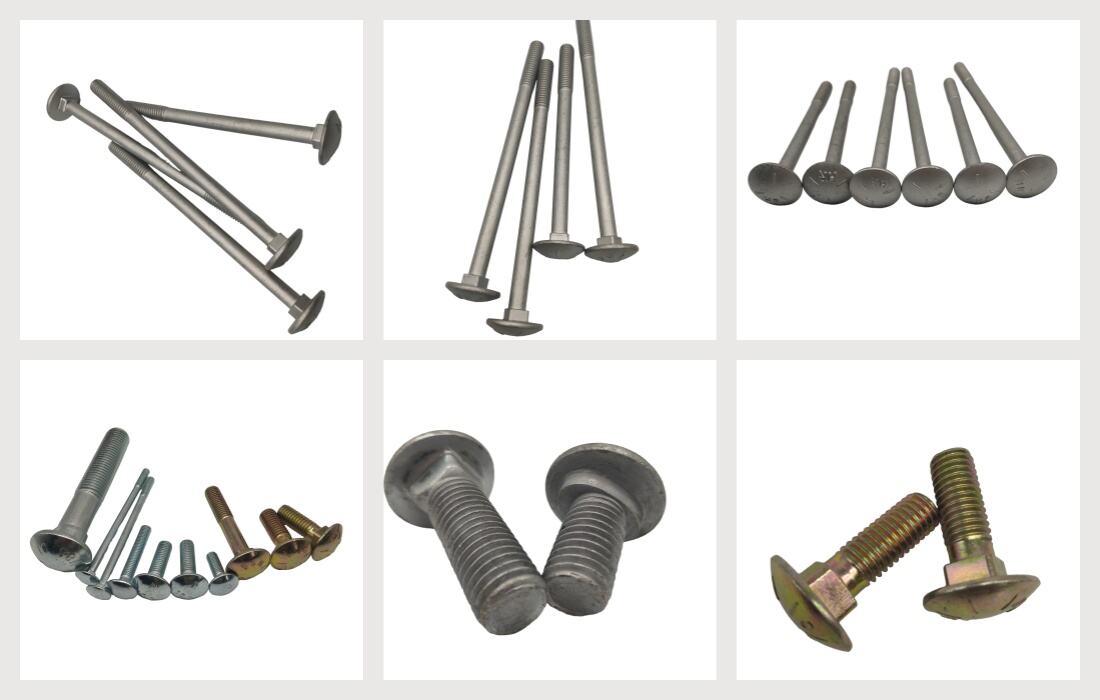

quality nuts and bolts

Quality nuts and bolts serve as essential fastening components in numerous industrial and construction applications. These precision-engineered components are manufactured using high-grade materials such as stainless steel, carbon steel, or alloy steel, ensuring exceptional durability and reliability. The manufacturing process involves strict quality control measures, including heat treatment, surface finishing, and dimensional accuracy testing. Modern nuts and bolts feature various thread patterns, sizes, and strength grades to accommodate different load requirements and environmental conditions. They incorporate advanced coating technologies that provide superior corrosion resistance and extended service life. The design specifications often include features like self-locking mechanisms, vibration resistance, and precise thread engagement to maintain secure connections under dynamic loads. These fasteners comply with international standards such as ISO, ASTM, and DIN, guaranteeing consistency and interchangeability across different applications. Their versatility makes them indispensable in industries ranging from automotive and aerospace to construction and machinery manufacturing.