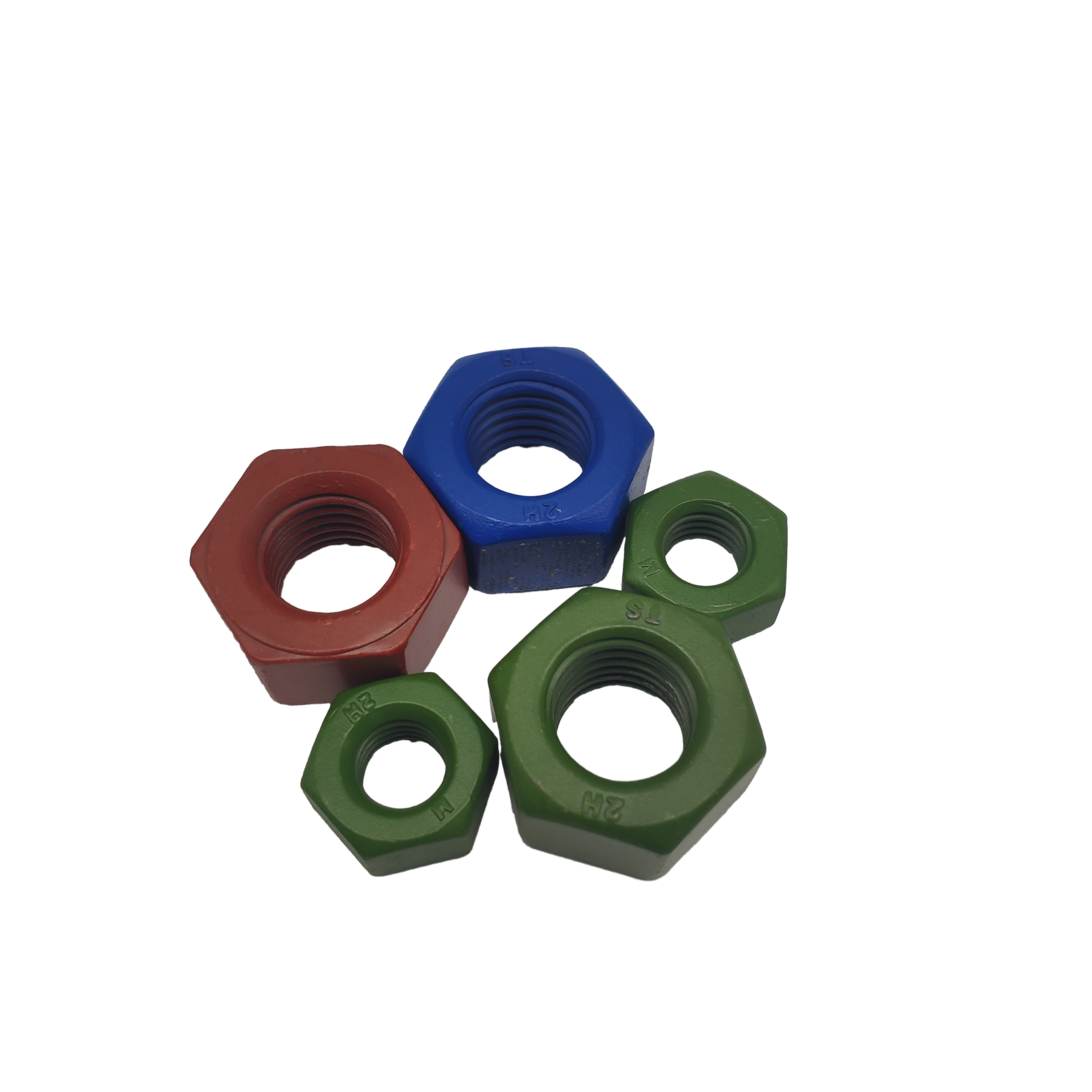

high quality custom bolts

High quality custom bolts represent the pinnacle of precision engineering and manufacturing excellence. These essential fastening components are meticulously designed and manufactured to meet specific requirements across various industries. Each bolt undergoes rigorous quality control processes, ensuring exceptional strength, durability, and reliability. The manufacturing process incorporates advanced materials science and cutting-edge production techniques, resulting in bolts that consistently exceed industry standards. These custom bolts can be produced in various materials, including stainless steel, alloy steel, and titanium, each carefully selected to match specific application requirements. The customization options extend to thread patterns, head styles, lengths, and diameters, allowing for perfect integration into any engineering project. Whether used in aerospace applications, heavy machinery, construction equipment, or specialized industrial processes, these bolts deliver superior performance under demanding conditions. The precision engineering ensures optimal load distribution, resistance to vibration, and excellent fatigue strength. Each bolt undergoes comprehensive testing for tensile strength, torque capacity, and material composition, guaranteeing reliability in critical applications.